C1100D5B main parameters

|

|

| Unit Type |

C1100 D5B |

|

| Performance parameters |

Backup (ESP) |

Normal load (PRP) |

|

| According to ISO 8528 |

|

| Power (kWe) |

906 |

823 |

|

| Capacity (KVA) |

1132 |

1029 |

|

| Fuel consumption rate (H) |

209 liters (under normal load and 100% load) |

|

| engine model |

KTA38-G5 |

|

| Generator model |

HCI634K |

|

| Controller model |

PC3.3 |

|

| Manufacturer |

Cummins Power (China) Co., Ltd. |

|

| Special function options |

· Parallel interface kit · Coolant heater · Coolant level sensor |

|

| · Electric ball winding temperature sensor · Electric ball heater · PMG permanent magnet motor |

|

|

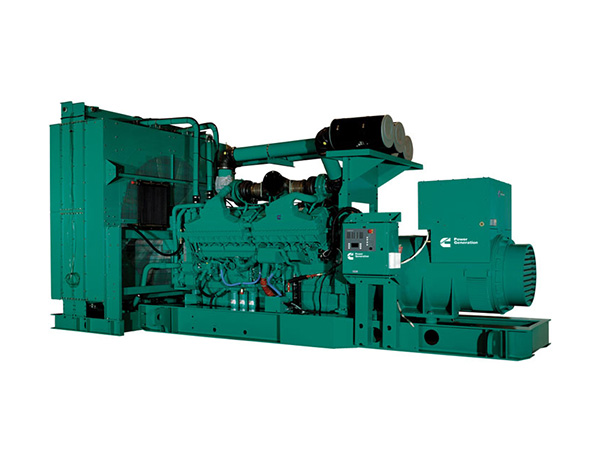

C1100D5B Product Description

|

|

| Cummins Power (China) Co., Ltd. is Cummins Power’s only generator set manufacturer in China. The products produced adopt Cummins Power’s global unified design, production and testing standards and are manufactured in China. Provide comprehensive quality assurance and provide one-stop service for the main components of the generator set, including the engine, generator and control system. |

| ·Comply with ISO8528-2005 and GB/T2820-2009 “Reciprocating Internal Combustion Engine Driven Alternator Set” standards. |

| ·The design and manufacturing units of the generator sets have passed ISO9001 or ISO9002 certification. |

| ·Cummins provides a 1-year or 1,000 operating hours quality guarantee and is responsible for the entire generator set warranty, including the engine, generator and control system. |

| ·A nationwide professional service network provides customers with 24-hour after-sales service and technical support. |

|

C1100D5B Requirements

|

|

| Altitude (m) |

≤1000 (power correction required if exceeded) |

Water quality pH value |

6.5~8 |

| fuel standards |

0# light diesel |

Relative humidity |

≤ 60% |

| Atmospheric pressure (kPa) |

≥89.9 |

Surface mold growth level |

GB/T2423.16/Level 2 |

| Engine oil standards |

Class CF/15W-40 or above |

Earthquake resistance |

Horizontal acceleration 0.2g Vertical acceleration 0.1g |

| Inlet air temperature (℃) |

≤40 |

earthquake relative intensity |

Chinese standard grade 8 |

|

| Note: All data in this data sheet are obtained when the engine is running with a fuel pump, water pump, oil pump, air filter and muffler, but does not include the alternator, air compressor, fan, optional equipment and driving parts. All data are based on conditions specified in the SAE J1349 standard – sea 90m (300ft.), atmospheric pressure 100kPa (29.61in.Hg), inlet air temperature 25°C (77°F), water vapor pressure 1.0kPa (0.30in.Hg) ), use standard 2# diesel or diesel that meets ASTM D2. Data are subject to change at any time without notice. |

|

C1100D5B Generator set parameters

|

|

| Unit type |

Open frame type (optional: silent type, mobile type) |

Speed(r/min) |

1500 |

| Unit Type |

C1100 D5B |

Emission Standards |

Second grade |

| Standby power (kWe) |

906 |

Frequency(Hz) |

50 |

| Normal load power (kWe) |

823 |

Voltage (V) |

400 |

| Unit size (mm) |

4374x1785x2229 (LWH) |

circuit breaker switch |

1600A 3P 690V, SS RMS, IEC |

| Unit weight (kg) |

8350 |

Random accessories |

Industrial muffler, bellows, engine oil, starting battery |

|

| Cummins Power is the world’s leading manufacturer in the design and manufacturing of pre-integrated generator sets from 55kVA to 2750kVA. All major components of the unit – engine, alternator, transfer switch and control system – are designed and manufactured by Cummins. We call this integration The Power of OneTM, this production method means that every component of the generator set is designed to work harmoniously with the entire unit from the beginning. |

|

C1100D5B Diesel engine parameters

|

|

| Diesel engine brand |

Cummins Cummins |

Fuel System |

direct injection |

| Diesel engine model |

KTA38-G5 |

cooling method |

Closed water cooling cycle |

| Diesel engine power (kWm) |

970 |

Governor type |

electric |

| Number of cylinders/cylinder displacement |

12/V type |

Start mode |

DC24V electric start |

| Compression ratio |

13.9:1 |

Air intake method |

Turbocharging, low temperature intercooling |

| Bore size × stroke (mm) |

159×159 |

Radiator temperature |

40℃ |

| Displacement(L) |

37.8 |

Engine oil temperature (°C) |

121 |

| Oil pressure (kPa) |

310~ 448 |

Configuration |

cast iron,60°,Four-stroke |

| Oil capacity (L) |

135 |

Speed(r/min) |

1500 |

| Engine coolant capacity (L) |

124 |

Idle speed(r/min) |

725~775 |

| Water tank coolant capacity (L) |

135 |

Overspeed limit (r/min) |

1725±50 |

|

| The entire series uses Cummins engines as power, with outstanding transient response characteristics, good fuel economy, environmentally friendly emissions, high reliability and long life cycle. With rugged and durable design and reliable electromechanical performance, Cummins products can also be applied to distributed power generation facilities in peaking power plants, peak shaving (or peak shaving) and power management at large commercial or industrial production sites. |

|

C1100D5B Generator parameters

|

|

| Generator brand |

Stamford |

temperature rise |

125℃ |

| Generator model |

HCI634K |

Power Factor |

COSΦ=0.8 hysteresis |

| Type |

Brushless, single bearing, rotating magnetic field |

Telephone harmonic coefficient: THF |

2% |

| Excitation system |

Permanent magnet, automatic voltage adjustment |

Telephone interference factor: TIF |

<50 |

| Winding structure |

2/3 pitch |

Wiring |

Y-type connection |

| Phase |

Three-phase four-wire |

Protection level |

IP23 |

| Insulation level |

Class H |

radio interference |

Meets the G and N levels of BS800 and VDE |

| cooling system |

direct drive centrifugal fan |

Applicable environment |

Less than 1km above sea level, 40℃ ambient temperature |

| fulfill the standard |

Comply with GB755, BS5000 Part 3, VDE0530, NEMAMG1-22, IEC-34, CSAC22-100 and AS1359 |

|

| The entire series uses Stanford generators, which have excellent excitation characteristics, allowing the diesel generator set to withstand high-power instantaneous loading, with small voltage fluctuations and rapid recovery. Cummins-manufactured alternators, with their high performance and low impedance, provide excellent voltage waveforms and motor starting performance in applications with high power requirements, such as data centers, hospitals and industrial facilities. |

|

C1100D5B Control system parameters

|

|

| Controller model |

PC3.3 |

panel |

LCD,LED backlight indication |

| Type |

PowerCommanddigital |

Operation surface facing |

Device side |

| language |

Multiple countries (including Chinese and English) |

voltage regulation |

Digital three-phase voltage detection, full-wave rectification |

| interface |

PCCNet and Modbus |

Monitoring and protection |

Real-time full-process monitoring, can support remote |

| Power supply |

12V and 24DC batteries |

extensions |

Extended parallel (peak shaving/base load) distribution capabilities |

| Switching System (AMF) |

Load switching operations can be realized in open switching, closed switching, and soft switching (ramp) modes. |

| Standards compliant |

Comply with UL, NFPA, ISO, IEC, Mil Std, CE and CSA standards |

|

| Power Command®The control system is a microprocessor-based generator set monitoring, metering and control system designed to meet the needs of generator sets powered by Cummins engines. This control system provides a convenient and concise human-machine interface for the generator set, realizing digital voltage regulation, digital speed regulation and engine set protection. All control functions are integrated into a single control system, which has higher performance than traditional generator set control systems. performance and reliability. The control system has been designed and tested taking into account the harsh conditions found in typical generator set applications. |

|

C1100D5B Installation parameters

|

|

| Minimum ventilation volume (m3/s) |

16.5 |

Minimum computer room area (mm) |

6100×4000×3500(LWH) |

| Combustion air volume (m3/s) |

1.21 |

Air duct length (mm) |

500 |

| Minimum air inlet area (m2) |

4.5 |

Height from the ground (mm) |

≈700 |

| Minimum discharge area (m2) |

3.5 |

Smoke exhaust pipe height (mm) |

3000 |

| Water tank exhaust outlet size (mm) |

1702×1575 |

Cement foundation thickness (mm) |

>150 |

| Daily fuel tank capacity (L) |

1000 |

Maximum back pressure (kPa) |

10 |

|

| Note: The installation should be adapted to local conditions according to the site conditions. Except for the fixed parameters of the equipment, the installation data in the table are conventional data recommended by Cummins. Please inform the user. |

|