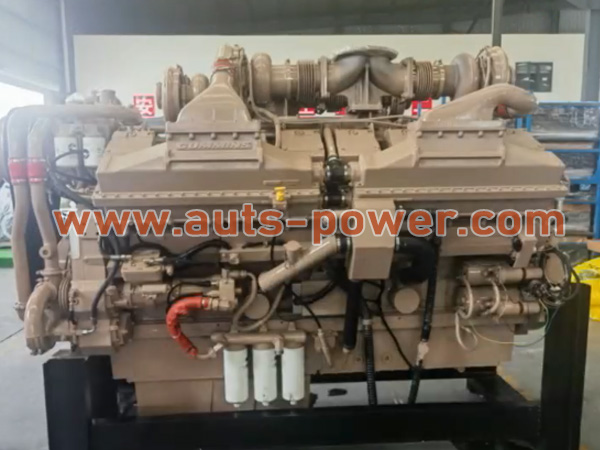

Cummins QSM15 77C Construction Machinery Engine

Emission Certification China MEP CS III

Rating Types Restricted

All data is based upon the engine operating with fuel system, water pump, and with inlet restriction and exhaust restriction at or below

datasheet limits. The alternator, fan, optional equipment, and driven components are not included. Coolant flows and heat rejection data is

based on a coolant mixture of 50% ethylene glycol and 50% water.

All data is subject to change without notice.

Intake Air System

Maximum allowable air temperature rise over ambient at intake manifold (naturally

aspirated engines) or turbo compressor inlet (turbo-charged engines): *This

parameter impacts emissions, LAT, and/or altitude capability

30.6 delta deg F 17.0 delta deg C

Cooling System

Maximum CAC outlet temperature at less than or equal to 25 deg C (77 deg F)

ambient 122 deg F 50 deg C

Maximum allowable pressure drop across charge air cooler and OEM CAC piping

(IMPD) 4.0 in-Hg 13.5 kPa

Maximum coolant temperature for engine protection controls 228 deg F 109 deg C

Maximum coolant operating temperature at engine outlet (max. top tank temp) 225 deg F 107 deg C

Heat rejection to Charge Air Cooler* at Performance Table RPM points: Governed Power: 107 kW (6076 BTU / min) Peak Torque: 71.5 kW

(4065 BTU / min) *Heat Rejection to CAC is collected at standard engine test conditions of 25 deg C / 77 deg F turbo air inlet temperature.

Please refer to the discussion section in the Advisor Installation Requirement (AIR) Report for Compressor Outlet Temperature and CAC

Heat Rejection adjustment procedures for other test conditions.

Exhaust System

Maximum exhaust backpressure imposed by exhaust system (if DPF is present, the

limit is at soot level after regeneration or cleaning) 3.0 in-Hg 10.0 kPa

Recommended exhaust pipe size (inner diameter) 5.0 in 127 mm

Maximum exhaust backpressure imposed by exhaust system for alternate pipe

diameter (if DPF is present, the limit is at soot level after regeneration or cleaning) 3.0 in-Hg 10.0 kPa

Alternate exhaust pipe size (inner diameter) 4.57 in 116 mm

RPM for maximum exhaust backpressure 2000 RPM 2000 RPM

Lubrication System

Nominal operating oil pressure at minimum low idle 18.9 psi 130 kPa

Nominal operating oil pressure at maximum rated speed 39.2 psi 270 kPa

Minimum engine oil pressure at minimum low idle (for engine protection devices) 10.0 psi 69 kPa

Fuel System

*Fuel cooling requirements with diesel fuel

Maximum supply fuel flow 430 lb/hr 195 kg/hr

Performance Data

Maximum low idle speed: 1200 RPM

Minimum low idle speed: 600 RPM

Maximum overspeed capability: 2625 RPM

Maximum continuous power: 406 kW (544 hp)

Maximum continuous speed: 2000 RPM

Cranking System (Cold Starting Capability)

Minimum cranking speed: 100 RPM

Maximum OEM parasitic load at 0 deg F and minimum cranking speed with all

required starting aids before over crank protection limits. 443 lb-ft 600 N-m

Maximum OEM parasitic load at 10 deg F and minimum cranking speed with all

required starting aids before over crank protection limits. 443 lb-ft 600 N-m

Required Starting Aids: Intake Air Heater Required, None

Minimum ambient temperature for unaided cold start at maximum OEM parasitic load 5.0 deg F -15.0 deg C

Minimum ambient temperature with grid heater only at maximum OEM parasitic load -31 deg F -35 deg C

Minimum ambient temperature with coolant and lube heater at maximum OEM

parasitic load -42 deg F -41 deg C

The above is general technicial information of Cummins QSM15 77C industrial application Engine. It is also for us to supply the Cummins QSM15 77C genuine parts and engine units with clutch ASSY.

Cummins Construction Engine,Cummins Marine Engine,Cummins Pump Drive Engine,Cummins Generator Drive Engine,Cummins Automotive Engine,Cummins Power Generation,Cummins Engine Parts